A company-wide production of micro-electronic-driven injection molding machine Microsystem50, the injection volume can change from 0.025cm3 to 1.1cm3, can be used to shape a single piece of 0.1g in the following micro-plastic parts. The injection molding machine uses a modular design method, the plastic, metering, injection and other units separated, and then through the modular assembly technology to complete the assembly of the machine. While also increasing the quality control module, plastic parts can be achieved online quality control. In addition, vacuum suction of mobile robots, storage devices for blister packs, and complete demolding monitoring equipment with cameras, as well as the corresponding cleanroom technology, are integrated into one manufacturing unit.

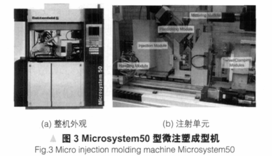

Molding plastic plastic melt through the diameter of 14mm screw into the measurement unit, the precise measurement and then enter the injection unit. The metering unit consists of a high-precision position control piston and a pressure sensor to ensure precise control of the injected melt volume and return pressure. Injection unit through the servo control of the cam mechanism to drive a diameter of 5mm plunger, thus ensuring the plunger in a very short period of time can get a higher speed, and with high enough pressure to melt quickly into the micro-mold Cavity. In order to meet the requirements of micro-melt rapid filling, Microsystem50 injection machine also provides up to 760mm / s injection speed, the maximum injection pressure of 262.5MPa, dry cycle of 1.8s. The appearance of the whole machine and the structural principle of the injection unit are shown in Fig

Reprinted from: http://www.sljx360.com/sljxa-260/

上一条: EPS energy-saving type shape molding machine

下一条: EPS BATCH PRE-EXPANDER