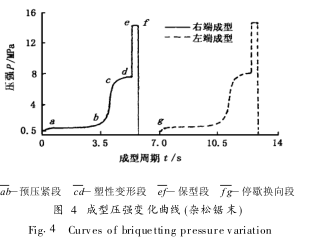

As can be seen from Figure 4, the right side of the piston plunger in the sleeve to move a stroke to complete the pre-compression → plastic deformation → type → stop for a molding cycle. After stopping, the left piston plunger enters the next forming cycle. Normal operation, the minimum pressure required for the minimum pressure, the basic air stroke hydraulic pressure, piston rod to stop moving, into the warranty section, the required pressure section of the largest section, to the hydraulic system rated pressure.

If the docking section (time) is constant, increase the forming cycle, then the maintenance section (time) increased, the type of energy consumption increased, productivity decreased; if the increase in stop time, although the molding pressure unchanged, but reduced productivity. The molding machine in the basic molding, maintenance and change the time required under the premise of the molding cycle of 7 s.

Source: http: //www.sljx360.com/sljxa-339/

上一条: Unique machine structure of EPS shape molding machine

下一条: EPS shape molding machine - Control System